페이지 정보

Angle-Adjustable Stand Type Nozzle Vacuum Packaging Machine

본문

SPECIFICATION

| MODEL | AZA-450ES | AZA-600ES | AZA-800ES | AZA-1000ES | |

|---|---|---|---|---|---|

| Sealing Bar Length [㎜] | (W)544 × (L)1340 × (H)1153 | (W)656 × (L)1340 × (H)1153 | (W)846 × (L)1340 × (H)1153 | (W)1062 × (L)1366 × (H)1374 | |

| Sealing Bar [㎜] | Length | 450㎜ | 600㎜ | 800㎜ | 1000㎜ |

| Width | 10㎜ (Option:5㎜) | 10㎜ (Option:5㎜) | 10㎜ (Option:5㎜) | 10㎜ (Option:5㎜) | |

| Weight [kg] | 55㎏ | 60㎏ | 65㎏ | 80㎏ | |

| VOLTAGE | 1PH 110V or 220~230V 50/60HZ | 1PH 220V 3PH 380V | |||

| REQUIRED AIR PRESSURE | 5-7 kg/㎠, maximum vacuum about 80㎪ | ||||

| Vacuum degree control | Vacuum sensor adjustment (unit: ㎪) / Timer adjustment (unit: 0.1 seconds) | ||||

| VACUUM PUMP | Ejector vacuum pump type, oil vacuum pump, oilless vacuum pump (Refer to selection method of vacuum pump) | ||||

| Max. Instantaneous consumed electricity | 1.8 ~ 4.0㎾ (relying on sealing bar's length and width) | ||||

| MAX. FINAL VACUUM | generally 85㎪ in case of using ejector type vacuum pump | ||||

| VACUUM VISUALISATION | appears digitally on LCD panel of control box | ||||

| PROCESS SETTING | The control unit memorizes various combinations of vacuum, gas flush & seal among MODE 1 ~ 8, besides S mode for only seal and V mode for only vacuum & seal. | ||||

※ Longer sealing model can be manufactured as a customized model. Ex) 1800mm

ACCESSORIES ( FREE OF CHARGE )

| 1) SPARE PARTS - HEAT WIRE, TEFLON SHEET, FUSE |

| 2) TOOLS - WRENCH SET, SPANNER, DRIVER |

| 3) OTHERS - WORK trAY, TOOL BOX |

What's the Nozzle Type Vacuum and Gas Flushing Packaging Machine?

It is a new concept of vacuum packing machine using a nozzle to suck air directly out of the bag so that it overcomes many shortcomings of the chamber type vacuum packing machine.(Refer to Chamber type vs Nozzle type)

- A method to suck air out of the bag

- Fast work speed

- Little restricted from the size of products (possible to vacuum and gas flushing packing up to 200Liter with AZV-Series)

- Vacuum packing for contents with high temperature (impossible with chamber type vacuum packing)

- In vacuum packing, no product damage caused by an instant discrepancy in pressure

- Various vacuum pumps can be applied according to products (pneumatic pump, oilless pump and oil pump)

- Multi-functions

- Sealing, vacuum packing, vacuum and gas flushing.

- Free adjustment for vacuum degree and gas

- Vacuum packing at low vacuum possible(3kpa at lowest)

- Gas flushing and substitution for the purpose of packing (impossible with chamber type vacuum packing)

- Neat and tidy packing shape

- In vacuum packing, products can be arranged freely

- Various option

- Various vacuum pumps can be applied according to products (pneumatic pump, oilless pump and oil pump)

STRUCTURE OF AZ-SERIES PRODUCTS

-

- Double heat wireb

- ① The fumction of gas flushing and gas substitution are included in the basic function

-

- Double heat wireb

- ② Pneumatic utility (air regulator with filitering function) is attached to maximize work efficiency

-

- Water filter

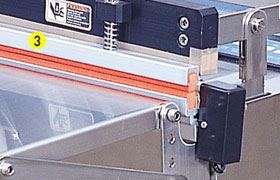

- ③ Fuses for circuit protection are attached

Structure of AZ-Series products

-

- Double heat wire00

- ① Control box Detachable(easy for after-sale service)

-

- Double heat wire

- ② The best quality caster is attached for easy moving and fixing

-

- Water filter

- ③ In case of using a thick film to pack, upper and lower double hot wires are attachable

-

- Water filter

- ④ 회사명, 날짜, 유통기한 등을 표시 인자기능(옵션사항)

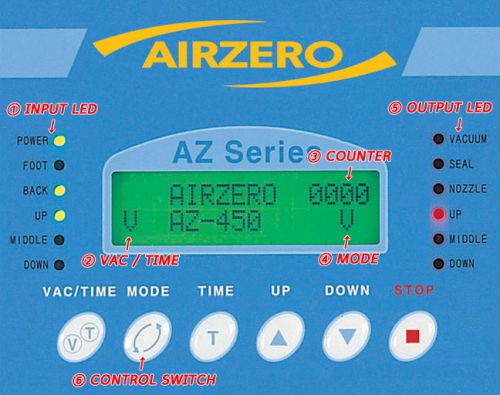

Function and Use of each button of control unit

This button decides the type of work among the following process

It is a new concept of vacuum packing machine using a nozzle to suck air directly out of the bag so that it overcomes many shortcomings of the chamber type vacuum packing machine.(Refer to Chamber type vs Nozzle type)

| ①INPUT LED | 전후진입형 |

|---|---|

| ②VAC / TIME |

V : Vacuum Degree (Kpa) of vacuuming The machine is operated by the preset vacuum degree. If you select 45, the vacuum works until the vacuum degree for the inside of vacuum bag approaches to 45 Kpa and the nozzle moves backward after that. Therefore, it is not related to vacuuming time T : Time of vacuuming The machine is operated by the preset time for vacuuming. When you select 25, the vacuum works for 2.5 second and the nozzle moves backward after that |

| ③COUNTER |

| ④MODE |

V:Vacuum, G1:Gas1, G2:Gas2, S:Convert to vacuum, gas1, gas2, adhesive, V at the bottom right of the LCD is vacuum, G1 is gas once, G2 is gas twice, S is adhesive

|

|---|---|

| ⑤OUTPUT LED | |

| ⑥CONTROL SWITCH |

This button decides target time or target degree of each process the user wants to get. With each pressing of TIME button, the turns are changed one by one from VACUUM1, VACUUM2, GAS1, GAS2, and SEALING to COOLING.

Then, for each of them, you can adjust time or vacuum degree by UP and DOWN button. ( If V is set by using VAC / TIME button, the value below VACUUM1and VACUUM2 means vacuum degree ) UP / DOWN : Increase / Decrease time / vacuum degree for each selected process STOP : This is the Stop button. If you press the button, the machine comes back to the original state. So, the nozzle moves backward and the sealing bar moves up |

Nozzle Type Vacuum and Gas Flushing Packaging Process

VACUUM PUMP of AIRZERO vacuum packaging machines

Note:OIL-LESS PUMP and OIL PUMP are much bigger and heavier than EJECTOR so that it cannot be equipped to desktop type suck as AZ-450E

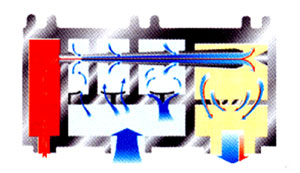

- Ejector vacuum’s merit

- AIRZERO vacuum sealer’s vacuum pumps are multi-stage ejectors.

- The energy supply is pressured gas, usually dry and filtered compressed air between 5~6bar.

- The multi-stage ejectors make better use of the energy in compressed air than a single ejector and therefore consume less energy.

- Large vacuum flows and high levels of vacuum are characteristic of multi-stage ejector.

- Energy usage can be reduced further by taking advantage4. of EJECTOR Energy Saving System.

- A pneumatic system, maintain the pumps air consumption at a minimum level by shutting off the pump when the desired vacuum level is reached.

- The pump restarts if the vacuum level decreases below an acceptable level.

- The pump must be equipped with a non-return valve.

- Various vacuum pumps can be appdded according to products (pneumatic pump, oilless pump and oil pump)

The merits of MULTI-STAGE EJECTOR are as below

- No electrical

- Lowest noise

- Never break down (no repair & no maintenance)

- Fast response

- No heat emission

- No spark (available in chemical industry)

- Easy to install

- No vibrations

- No oil mist

| Features | Multi-stage Ejector | General Ejector | Motor Driven Pump |

|---|---|---|---|

| Fundamental Design and Configuration |  |

|

|

| Energy Source | Compressed Air | Compressed Air | Electric Motor |

| Energy Consumption | Low particularly when using air saving kit and when pump is used only on demand | High relative to performance | High because pump has to run continuously regardless of application |

| Heat Production | None | None | High |

| Operating Noise Level | Low( approx. 50-60dBA) | High(Approx 75dBA) | High above 75dBA |

| Ease of Installation | Easy, quick and cost effective, very little space required, lightweight and easy to mount local to requirement | Simple | Difficult, electrical control required for motor, large space needed with robust construction to mount motor and pump. Large control valves needed |

| Servicing | Non required | Not easy to dismantle | Regular servicing required |

| Response Time | Immediate | Almost Immediate | Slow |

| Ability to produce high vacuum flows combined high vacuum levels | Possible with lots of pump options | Not possible | Possible but long evacuation times |

| Resilience to Corrosive and Hazardous Environments | Very Good due to no moving parts and PPS housing | Dependant on housing material | Special pumps required |

EJECTOR PUMP

| EJECTOR PUMP | |||

|---|---|---|---|

| Model No. | Maximum Vacuum capacity (Kpa) |

Displacement speed (l/min) |

Con-sumed air (l/min) |

| VTX -20 | 80 | 124 | 86~96 |

| VTM -50 | 80 | 647 | 150~200 |

| Compressor is impossible to be built-in | |||

OILLESS PUMP

| OILLESS PUMP | |||

|---|---|---|---|

| Model No. | Maximum Vacuum capacity (Kpa) |

Displacement speed (l/min) |

Con-sumed air (l/min) |

| 275V | 91.9 | 75 | 150 |

| 2120V | 91.9 | 120 | 200 |

| Compressor is possible to be built in, in the case ogf sub-stand attached model. | |||

OIL PUMP

| OIl PUMP | |||

|---|---|---|---|

| Model No. | Maximum Vacuum capacity (Kpa) |

Displacement speed (l/min) |

Con-sumed air (l/min) |

| SVO-100 | 103.1 | 100 | 250 |

| MVO-010 | 103.1 | 200 | 450 |

| MVO-020 | 103.1 | 400 | 950 |

| Compressor is possible to be built in, in the case ogf sub-stand attached model. MV0-010 & MV0-020 Models are only for AZV Compressor built-in possible |

|||

Option of AIRZERO vacuum packaging machines

| Model | Option Name | The Function |

|---|---|---|

| All | Additional program memory function of PLC | It makes you can preset and memorize various work forms combined with vacuum, gas flushing and sealing respectively among 1 ~ 8 mode, besides S mode for only sealing and V mode for only vacuum and sealing. It is convenient in the case that there are various types of products to pack |

| Double Hot Wire | For thick film | |

| Air Blower | For cleaning inside vacuum line by blowing out any particle with compressed air. | |

| All ( AZV-type has this as its basic function) | Long Nozzle | The degree that nozzle moves forward can be adjusted within about 10 cm from the sealing bar. So, in the case thick product like many fold tray, user can set the nozzle to move deeply into packing film so that it can get close to the packed object. If the nozzle is too far from the packed object, both sides of packing film stick to each other which prevents air from being sucked out. |

|

All except for desktop type |

Water Filter | If handling items are liquid like water, have to use this filter. |

| Powder Filter | If handling items are powder or particle-contained products, have to use this filter. | |

| Oil-less Pump | For built-in air compressor in machine with more vacuum power ( In many general cases, EJECTOR vacuum is more convenient than Oil-less Pump. So, please recommend EJECTOR vacuum unless there is any special reason to use Oil-less Pump.) | |

| Oil Pump | For built-in air compressor in machine with best vacuum power ( In many general cases, EJECTOR vacuum is more convenient than Oil-less Pump. So, please recommend EJECTOR vacuum unless there is any special reason to use Oil Pump.) | |

| Desktop type | Setting for clean-room with less than 1000 class | Upper cover for body, air exhausting line and pump, etc |

Options’ pictures

-

- Double heat wire

- Are two black heat wire plastic holder covers, which means upper and lower sealing bar has heat wire respectively

-

- Water filter

- The water filter’s element is fiber material to catch as much water as possible

-

- Air blower

- The yellow button is air blower Double heat wireb

-

- Double heat wireb

- There are two black heat wire plastic holder covers, which means upper and lower sealing bar has heat wire respectively

-

- Powder filter

- The powder filter has many wrinkles to catch as much power particle as possible

Long Nozzle

You can see the nozzle’s forward movement degree from the sealing bar is adjusted.

Clean-room setting

Cleanroom option: This option is for cleanroom work place (100 class), we provide with air blower (Fan) and hose (5m). However, if customer wants to purchase Air blower (Fan) and hose, we provide without fan and hose. Please let us know a diameter of fan if you want to purchase a fan by yourself.

Selection Procedure of AIRZERO vacuum packaging machines model

You can select a AZ-Series model most suitable for your working environment by referring to the below procedure.

| · | Basic type |

|---|---|

| H | Height control type |

| A | oblique type |

| V | a vertical type |

The slope-adjustable product goes up to 45 degrees above the product. It's adjustable, so the packaging of liquids is also glass.

| sealing length | Basic type | a vertical type |

|---|---|---|

| 450 | O | X |

| 600 | O | O |

| 800 | O | O |

| 1100 | X | O |

depending on the width of the bag to be packed Sealing area can be selected

| E | Ejector pump |

|---|---|

| L | Oilless pump |

| H | Oil pump |

Applicable to various vacuum pumps depending on packaging products Pneumatic pump, oilless pump, oil pump

| . | tabletop shape |

|---|---|

| S | Stand type |

Choose your product depending on where you want to work

| · | Single type |

|---|---|

| D | Upper and lower double type |

The heating wire can be selected depending on the thickness of the bag to be packaged

| · | Without phosphorus |

|---|---|

| P | Attachment of imprinter |

Date of manufacture, expiration date, lot no. etc. Attaching a displayable phosphor

However, if sealing length of 800mm is combined with double heat wire, sealing width is possible only to be 5mm

Application of Nozzle Type Vacuum and Gas Flushing Packaging Process

- Nozzle Type Vacuum and Gas Flushing Packaging Process

- Semi-conduct & other Industrial goods

- Cleanroom Vacuum Packaging

- Prevention of Oxidation

- Prevention of moisture

- Free from Static Electricity

- Elimination of Particle

- Nitrogen flushing

- Substitution for Oxygen

- Protection of Goods from external shock

- Prevention of Moisture

- Packaging externally as same as vacuum Packaging by adjusting gas volume

- Use : Confectionary & Grains

- Nitrogen & Carbon dioxide flushing

- Carbon dioxide for inhibitory action against germs

- Use : Fishes & Meats

- Nitrogen, Carbon dioxide & Oxygen flushing

- Keeping up of Freshness & Nutrition by inhibitory action

- against respiration & photosynthesis

- Use : Vegetables & Fruits

Optional

SPECIFICATION| BUYER LIST - INDUSTRIAL GOODS | |

|---|---|

| FIELD | BUYER |

| Dried fish and meat | Donghae Geonomul, Deoksu Yootong, etc |

| Vegetables | Singsingwon, Pulhananongwon, Wonhyeop, Myeongmun Catering, Seongdo Nongsan, Biosystech. Seolimfarm, etc |

| Grains | Hyunmenara, Baegam Nonghyup, Cheongjeong Migokcheorijang, Naju Agricultural Technology Center, ATC company, etc |

| Fish and meat | Songdo Susan, Gil Susan, Daeseon Mulsan, Mokpo Suhyup, Leecadena, etc |

| Nuts | Hanbando Foods, Nakaoka Foods, etc |

| Hot goods | Hanjung Nongsan, Midang Namwongol Chuotang, etc |

| OTHERS | Bamsong Foods, Mokpo Suhyup, Damyang Bamboo Nara, Petworld, Kyunghee University, etc |

| BUYER LIST - INDUSTRIAL GOODS | |

|---|---|

| FIELD | BUYER |

| SEMI-CONDUCTOR & WAFER | Motorola, Crossmos Ltd. Seoul Semiconductor, Hynix Semiconductor, Comico, Venture town in Suwon University, Iljin Diamond and etc |

| IC & ELECTRONIC PARTS | Terrasem, Samsung Electro-Mechanics, Samsung Electronics Co. in Gumi, LG Electronics, Samsung Techwin and etc |

| OPTICAL - related | Sekonix, Nano Optics, Taeyoung Optics, Bangju Optics, Haeseong Optics, LT ULTRA and etc |

| GENERAL MACHINERY | DF Tech, Cinos Engineering and etc |

| MOBILE PHONE - related | Korea Alps, SI Telepac, Daeho MMI, Sina Tech, Samyoung Electronic Communications and etc. |

| RESEARCH EQUIPMENT | Institute for Advanced Engineering, Korea Electronics Technology Institute, Korea Atomic Energy Research Institute, Byeongjeom Agricultural Technology Research Institute and etc |

| MEDICALS | SAEROMPHARM, Greencross, Fresenius-kabi Greencross, Sang-a Medical, Tsumura, ID Biochem, Department of pathology of Seoul National University and etc |

| OTHERS | Korea Shinetsu Silicon, Thai Shinetsu Silicon and etc. Ministry of National Defense, The Jungang Research |